Springs

In addition to compression and tension springs, our product range of “classic springs” also includes torsion springs. In addition to classic spring steel, we can also process all materials currently available on the market, as well as special alloys and special materials such as titanium. Surface treatments/finishing such as galvanizing, painting, plastic coating, passivating, shot blasting, etc. We assign this to our long-standing partners. We also offer the final heat treatment of the parts or the grinding of the spring ends from a single source. The areas of application for our springs range from the automotive industry to the electrics/electronics industry to medical technology and the aviation industry, locksmith goods, sports and leisure items, agricultural machinery and many more.

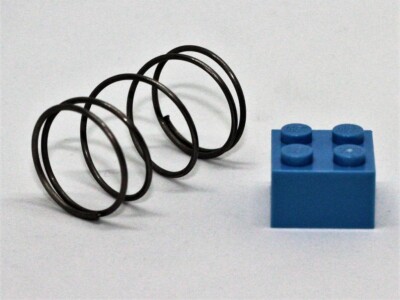

compression springs

We manufacture compression springs in wire thicknesses from 0.1 to 30.0 mm on modern automatic spring winding machines. Electronic measuring and control devices as well as force measuring devices and optical measuring systems are available for quality assurance.

tension springs

We manufacture tension springs in wire thicknesses from 0.1 to 17.0 mm on modern automatic spring winding machines. Tension springs can be manufactured with a wide variety of eyelet designs. Electronic measuring and control devices as well as force measuring devices and optical measuring systems are available for quality assurance.

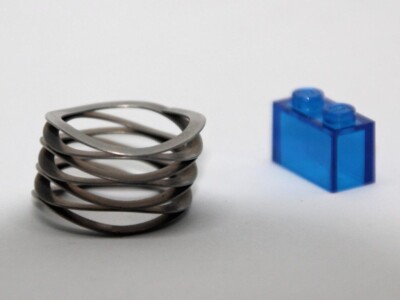

torsion springs

We manufacture torsion springs in wire thicknesses from 0.1 to 30.0 mm on modern automatic spring winding machines. Electronic measuring and control devices as well as force measuring devices and optical measuring systems are available for quality assurance. Torsion springs can be manufactured in all desired shapes and with all leg designs (bent, deburred, chamfered).